When sourcing sand for use in 100% acrylic sport coatings, it’s important to use quality sand. There is a large variety of sand characteristics when sourcing throughout the United States & around the world. Here are some important factors when researching sand for acrylic sport surfaces:

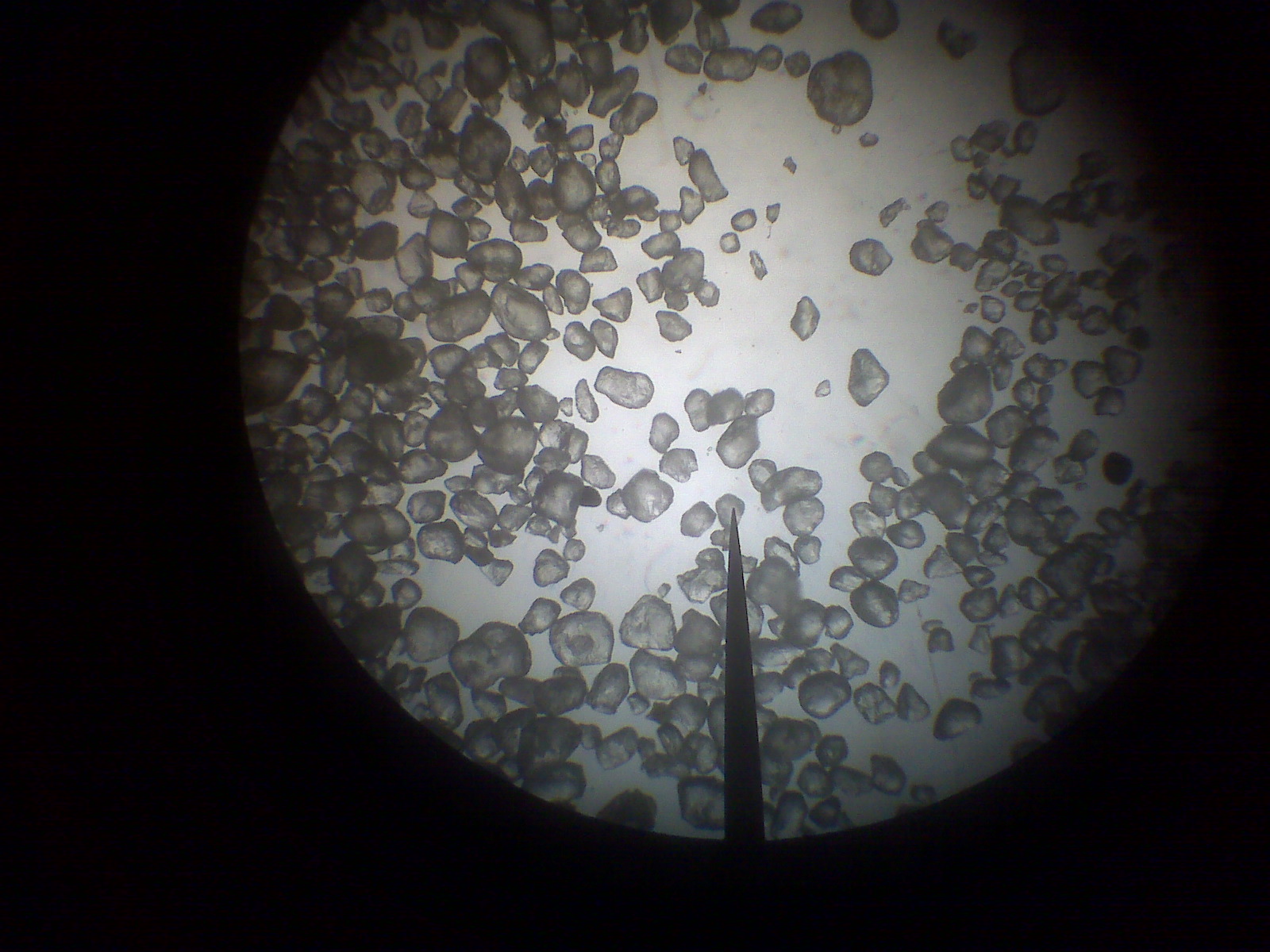

- For acrylic color coatings, shoot for a sieve size of 70-90 mesh. The higher the number, the finer the sand particle.

- The ideal shape for color coating sand is round. Angular sand can be used for a grittier texture, but it can also increase wear on the pickleball or slower play with tennis balls. Angular sand can increase wear on pickleballs and create more ball fuzz with tennis balls. Angular sand can also result in more visible application, or squeegee marks.

- Since the standard method of coating application is a soft rubber squeegee, the size of the sand sets the coating thickness. The larger the sand, the thicker the coating. This also affects the coverage rate. More coating is used with larger sand and less with finer sand.

- Look for sands with low-to-no dust. Dust in sand can lead to less vibrance and more chalky appearance of the color coatings. It can also diminish the UV resistance of the color and lead to earlier fading of the finish. When looking as a sand sieve analysis, look for low percentages in the “Pan”. The pan holds fines that fall through all of the sieve “screens” and lands in the pan at the bottom.

Are finer and coarser sands acceptable for use in color coatings?

When looking at a sand sieve analysis, there is never 100% of a certain size in any lot of sand. There is a range of particle sizes in various percentages within all sands. Most technical data sheets for sand will include the sieve analysis, and some of them will provide the average (or AFS). So if a specification calls for 100 mesh sand, it would be acceptable to use something close like a 80 to 90 mesh sand since it likely has particles within the mix that are over and under this range.

What is the best type of sand to use in Acrylic Resurfacer?

Acrylic Resurfacer is an industry-standard product that is used as the base coat(s) under colored acrylic playing surfaces. Acrylic Resurfacer is used for the following:

- Filler coat. Fills voids in asphalt or concrete pavement surfaces.

- Helps to hide crack repairs, low spot leveling and other surface repairs

- Provides texture on an existing smooth acrylic surface to prepare for consistent application of new textured color coatings. This helps to ensure the proper mil thickness of the color coatings, which leads to longer wear and superior hiding.

- Excellent primer coat for adhesion of the surfacing system.

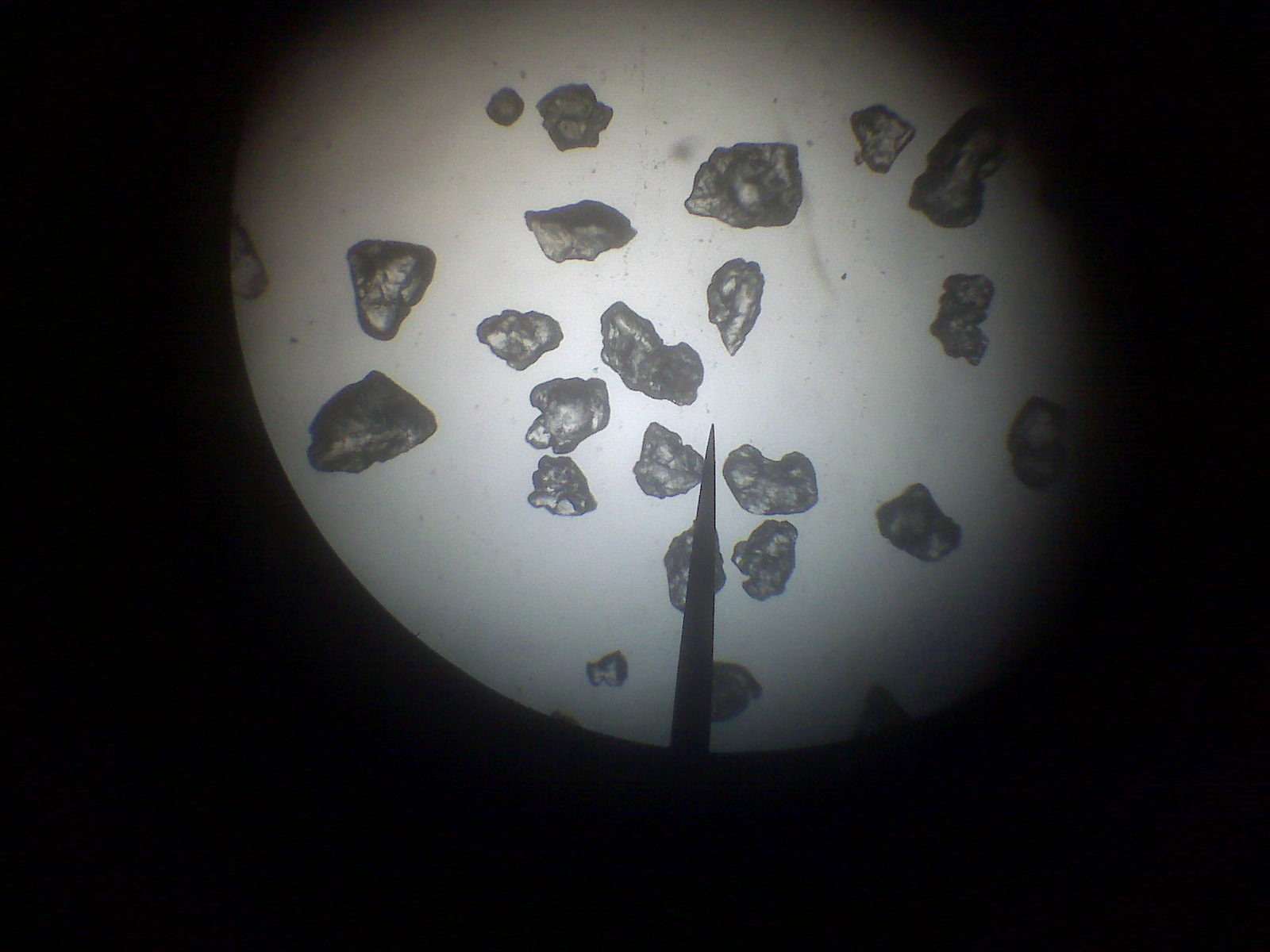

The size and shape of the silica sand used in acrylic resurfacer is directly attributed to the performance. Thus, it is recommended to use a larger & angular shaped silica sand somewhere between 40 to 60 mesh (clean and dust-free). This helps to create a thicker hiding coat which is also perfect for filling voids in pavement. If a finer sand is used in Acrylic Resurfacer, the filling and hiding capacity is greatly diminished.

Recommended sand for Acrylic Patch Binder

Acrylic Patch Binder is another common repair product that is used on acrylic courts. Patch Binder is a 100% binder that is mixed on-site with portland or hydraulic cement, and silica sand. It is used to fill and level birdbaths, or low areas where water puddles on a court surface. Patch Binder mix is also used to fill cracks on asphalt and concrete athletic courts. Since we want to fill low spots and cracks, it is ideal to also use a 40 to 60 mesh angular silica sand. This should be the same type of sand that is used in Acrylic Resurfacer.

Summary of Sand for acrylic sport surfacing systems

The correct sand shape and size is very important, when sourcing for acrylic sport surfacing systems. Contact your local SportMaster representative for more information & the best sources of silica sands. If you’re having trouble finding a good local source, you may want to consider buying factory-mixed coatings. SportMaster produces Acrylic Resurfacer and Color Coatings in both non-textured and factory-textured options.