One of the most frequently asked questions, especially in northern climates, is: Should I close my recreational courts for the winter? Once cured, acrylic court surfaces are very durable and require little maintenance. However, below are some items to consider.

Does ice and snow damage acrylic court surfaces?

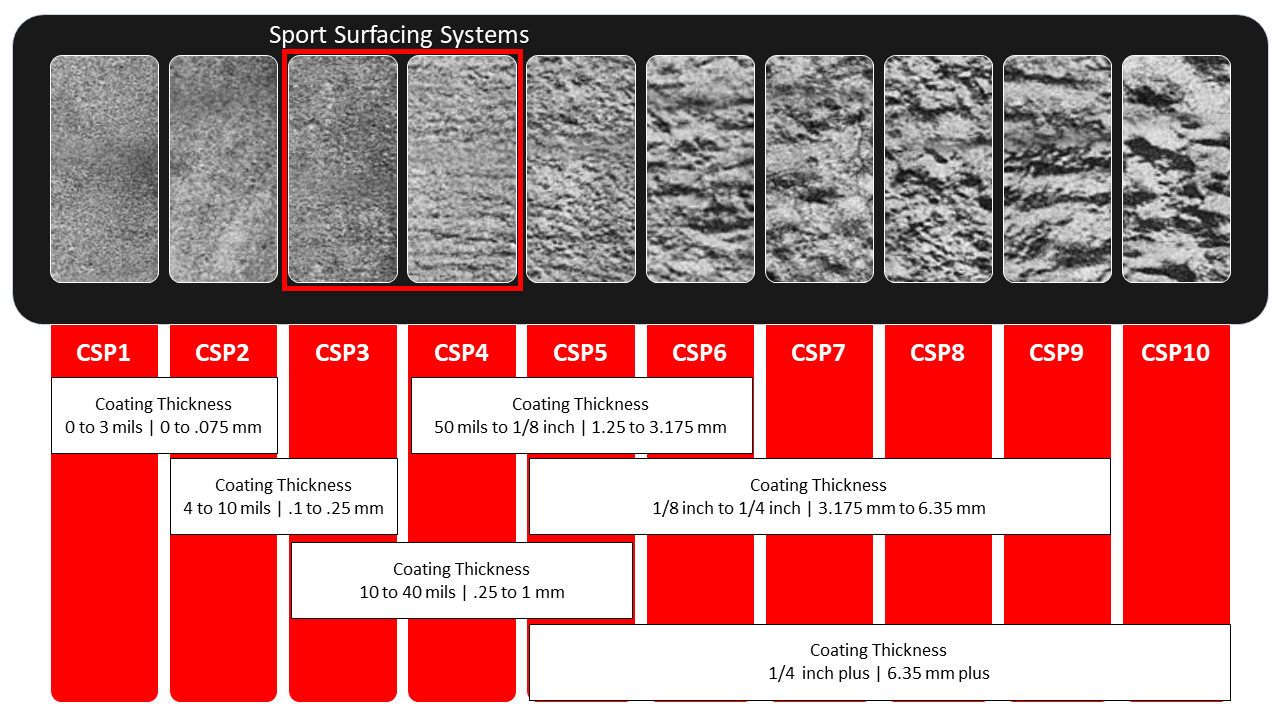

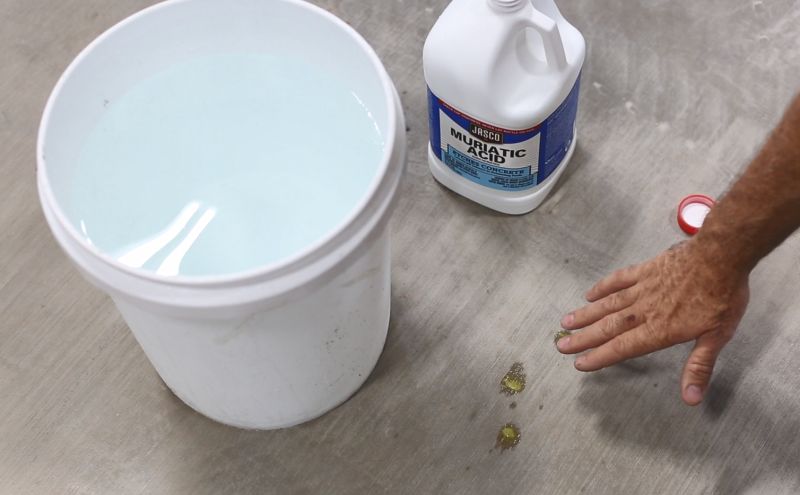

Athletic courts, like tennis, pickleball, and basketball courts, should be built with a 1% slope to allow positive drainage without creating difficult playing conditions. This helps the court surface to dry quicker, but also to prevent water damage to the acrylic surfaces. Acrylic court surfaces do not like to be submerged in water for long periods of time. However, as long as the coatings have time to dry, water doesn’t affect the longevity. Since ice and snow is in a sold state, it would not soak into the surface and cause damage as quickly as puddled water may do.

Snow Management & Debris | Winter Court Maintenance

The biggest issue with keeping your court open in the winter is snow management. There is no problem with playing on courts when it is cold outside. However, if you have piles of snow on the surface, here are a few things to keep in mind:

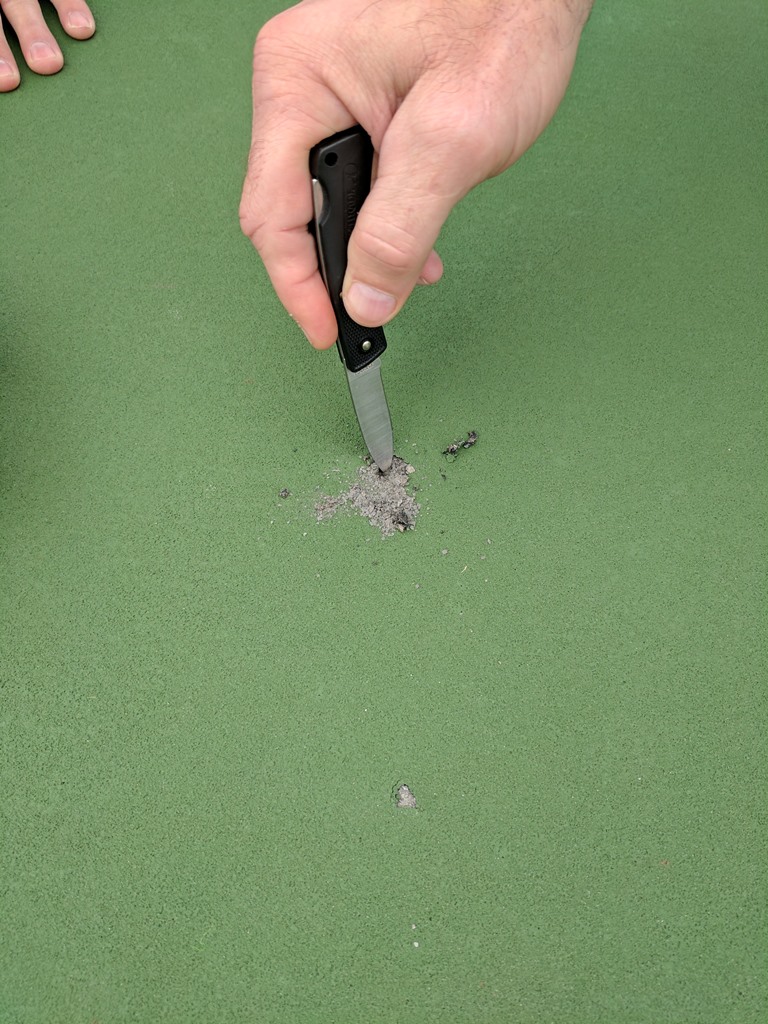

- Try to limit physical removal of snow and ice. (Metal shovels and tools with a sharp edge can damage the surface. Try to stick with plastic shovels or wait for snow to melt before playing.

- Using salt or other granule-type snow melt products can lead to extra abrasion to the surface. When playing on the courts, any debris under foot can damage or shorten the life of the coatings.

- Make sure to also remove any debris that has fallen, like leaves or pine needles. Not only does this minimize abrasion but it also prevents other organic staining or damage from wet rotting leaves.

Court Accessories During The Winter

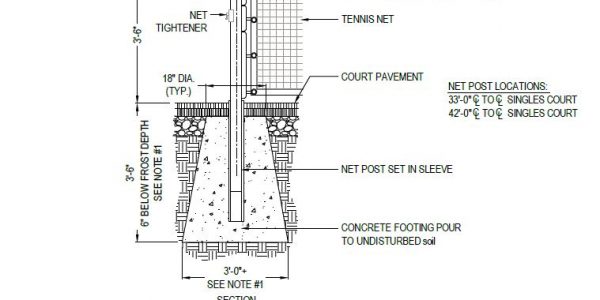

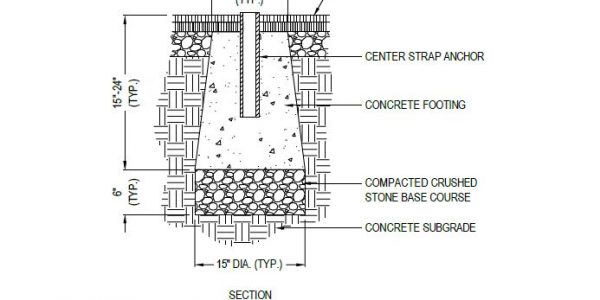

If you decide not to use your court during the winter, you may want to take down and store any windscreen that you are using. This will help to prolong the life of windscreen. If you decide to keep the tennis or pickleball nets up for winter play on nice days, you may want to reduce the tension on the net a bit. Not enough to let it flap around in the wind, but a little tension relief can reduce extra strain on the net post footers and pavement during cold temperatures. If you do decide to close your court for winter, remove the net and slide the tennis/pickleball posts out of the ground and cover the surface holes with a cap/plug.

Maintaining Positive Court Drainage

As previously mentioned, it’s very important for court surfaces to drain and not hold water. During the winter, and really throughout the year, keep an eye on the court and make sure that nothing is stopping the flow of your court drainage design.

- Make sure any drains around the court are not plugged with debris, like fallen leaves from the fall. This will prevent back-up of water onto the court surface.

- Keep vegetation trimmed around the edges of the court, especially on the low end of drainage. Failing to do so can also create a dam for positive drainage.

- The court should be built up a bit so that water can flow off the court to the drainage plan. Make sure dirt or other obstructions are lower than the court surface edge, as well.

Winterizing Your Tennis or Pickleball Court

Regardless of your decision to keep your court open for play during the winter, here are some court winterizing tips (recap):

- Before the weather gets too cold, make sure to examine your court surface for cracks. Fill the cracks with an acrylic crack filler to minimize the flow of water into the base of the court. The less water that you have freezing and expanding under the base, the longer your court will stay in good condition. Make sure to make these repairs far before the nighttime lows dip past 50 degrees F / 10 degrees C.

- Walk the perimeter of the court and make sure there is nothing blocking drainage on any side of the slab. Ensure that any visible drains are not blocked or plugged with debris.

- Keep the surface free of debris, such as leaves, pine needles, and all other tree matter.

- If you choose to close the court for winter, remove the net. Optionally, if your posts are removeable, you can slide them out and store them. If you do remove them, plug the surface holes with a cap (all post manufacturers make caps for the sleeves). If you leave the posts and nets up, take a little tension off the net during the winter.

- Avoid using sharp or potentially damaging tools on the surface for snow removal. Salt and snow melting pellets may shorten the life of the surface, so use sparingly and make sure to blow or broom off excess particles to minimize damage.