Question: How long should asphalt cure before applying sport surfaces?

Answer: New asphalt should cure a minimum of 14 to 30 days, prior to application of a sport surfacing system.

Asphalt Curing & Sport Surfacing Systems

Asphalt consists of rock, generally limestone, and liquid asphalt. The liquid asphalt, also referred to as asphalt cement or asphalt binder, is the “glue” that holds the rock together and enables the paving layers to bind to the prepared base.

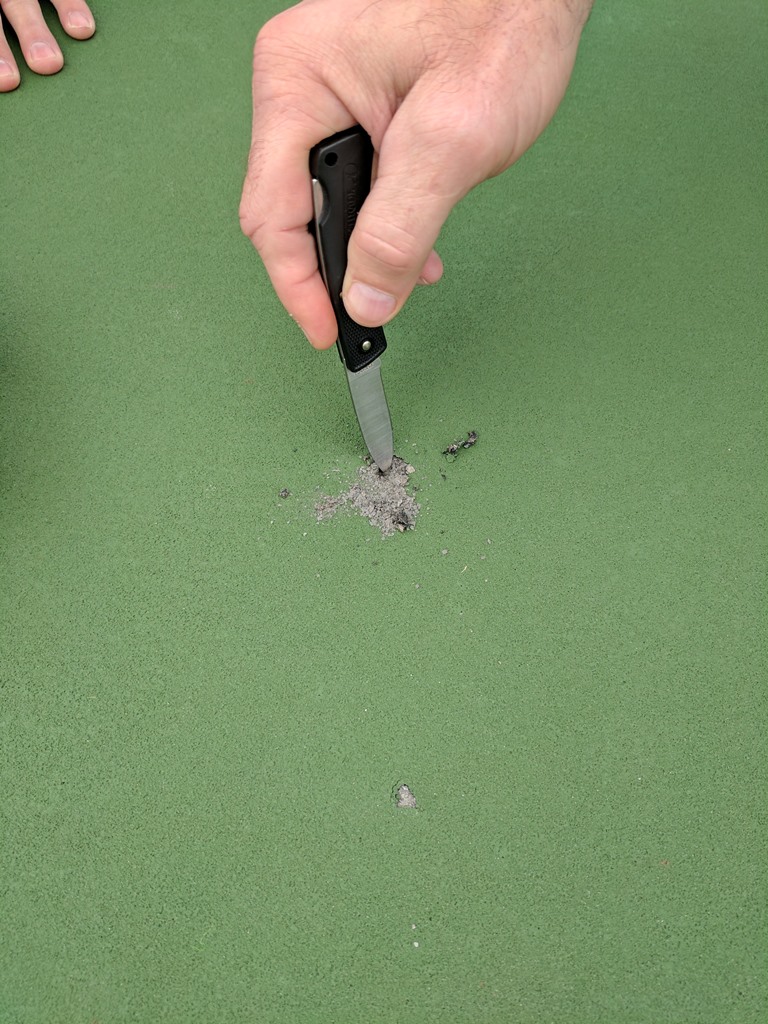

When asphalt is newly paved in place, it exudes some excess asphaltic oils during the initial curing of the slab. It’s important to let some of the oils cure out, before application of any coatings, sealants, and sport surfaces.

Risks of Inadequate Asphalt Curing Before Surfacing

If the asphalt is too rich with asphalt binder and hasn’t had the opportunity to cure, or release the initial gush of asphalt oils, it can potentially lead to:

- Lack of proper coating system adhesion (which may result in peeling and other paint and coating failures)

- Staining, yellowing, and discoloration of the sport surfaces and coatings.

What are prime conditions for asphalt curing?

Hot & sunny conditions will help to pull the rich asphalt binder up to the surface. Once the excess oils are pulled to the surface, it is also important to have rainfall. This helps to rinse some of the oils away and “unplug” the pavement voids. The combination of sun to draw the oils to the surface and water to rinse them away, allows for continuous prime curing conditions.

If the conditions are good, the asphalt can be ready to coat in a minimum of 14 days. The safer option is to wait 30 days, if time allows. If conditions are warm and sunny after paving, but the area experiences a drought, rinsing of the surface by manual methods can help to keep the curing process in motion. Indoor asphalt curing can take longer than 30 days, to ensure sufficient release of oils.

Since there are variables, and no actual testing processes to guarantee initial curing, it is best to allow proper time for adequate curing. Sport coating manufacturers & experienced sport surfacing contractors are the best source for recommendations, when it comes to proper application timing. Rushing to resurface your tennis, pickleball, or basketball court before the asphalt is ready can lead to expensive problems now or down the road.