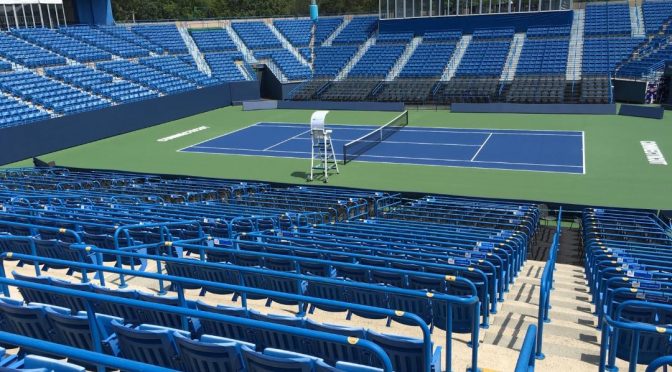

Athletic & recreational courts (tennis, pickleball, basketball, etc.) are built from either asphalt or concrete pavement. The type of substrate used is normally determined by region, cost, preference, availability or site access.

Each substrate (asphalt or concrete) has its own set of requirements, when it comes to application of acrylic sport surfaces. This bulletin will discuss how to properly prepare concrete for sport surfacing athletic courts.

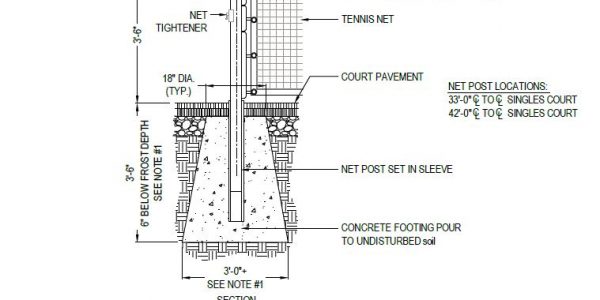

Concrete Court Construction

When it comes to proper concrete court construction, there is a long “to-do” list. As with anything, there is always a good, better, best list of what to do and why it is important. If you are considering having a recreational court built, we recommend getting a copy of the American Sports Builders Association’s construction & maintenance manual. They publish and sell these for tennis or pickleball, which is also useful for basketball and other sports. That being said, we will reference a short list of the most important factors, prior to application of acrylic surfaces.

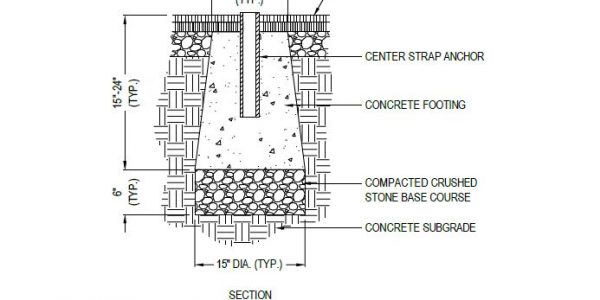

Install Vapor Barrier

Prior to pouring the concrete slab, a vapor barrier should be installed to prevent upward migration of ground moisture. This normally consists of two sheets of 6 mil polyethylene plastic sheeting, laid in opposite directions. Make sure it is overlapped and taped at the joints. The vapor barrier is on top of the stone base and under the concrete slab.

Ensure Adequate Perimeter Drainage & Slope

Another very important factor, when trying to minimize water accumulation under the concrete slab, is good perimeter drainage. If one or both of these items are lacking (vapor barrier & perimeter drainage), your court surface could be in danger of bubbles or blisters in the coating. In most cases, this will lead to peeling of coatings and bare spots down to the concrete. Court surfaces should be sloped at 1% in one direction, which is 1″ fall in every 10 feet. This helps to keep water flowing off the court and ensures fast drying surfaces and less standing water.

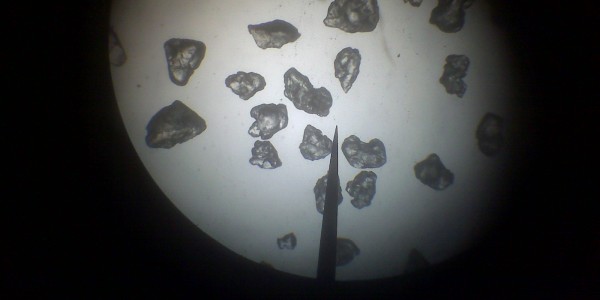

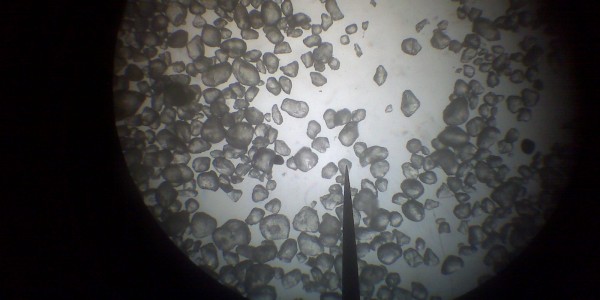

Medium-broom Finish or Similar Surface Texture

When pouring and finishing the concrete, make sure that the concrete contractor applies a medium-broom finish on the surface of the concrete. This is very important to a good physical bond of the sport coatings. A steel-troweled finish is too smooth and will also raise the chances of peeling surfaces. If the concrete is already in place and doesn’t have a medium-broom finish, you can use specialized equipment to achieve sufficient texture. The most commonly used piece of equipment is a shot blaster. For more information, check out our dedicated page on shot blasting concrete court surfaces.

Allow Full Cure Before Coating Application

The curing process of concrete is a chemical reaction that takes 28 days to complete. During the process, quite a bit of water is escaping from the slab and depositing high-alkaline salts on the surface. It is important to allow a full 28 day minimum cure, prior to moving forward with coating application. Also, after the full cure and prior to application of coatings, the concrete slab must be acid etched (or acid washed). This helps to create a neutral PH on the surface for an ideal chemical bond of coatings. This is fully explained on our page, acid etching concrete sport surfaces.

One more note on curing, avoid using curing compounds on concrete court surfaces. Once the concrete is poured, it will instantly begin to losing water via evaporation. If the temperatures are hot, water will leave the wet slab quickly, and this could lead to surface cracking (like mud cracking in a puddle). To prevent this, most concrete contractors spray curing compounds on the surface to slow down the evaporation of water. Many curing compounds are made up of oil based or incompatible materials that can leave a residue on the the concrete surface. This residue, or film, can potentially cause a bond breaker and lead to failure of the acrylic sport coatings. To avoid this situation, make sure the concrete contractor moisture cures the slab. This is performed by keeping the slab wet after pouring, with a covering of moistened burlap, a polyethylene sheet, or other curing paper. After 7 to 10 days, it can be allowed to dry and cure under normal conditions without the keeping the slab moist.

Not sure if curing compounds have been used, or you know they have been used? The surface can be shot blasted to remove any bond-breaking films. Note, you can pour a small amount of water onto the concrete slab to see if water beads up on the surface. If it does, there is likely a curing compound or sealant on the surface.

Application Of Concrete Primer & Sport Surfaces

At this point, the concrete slab should be ready to receive the sport surfacing system. Once the surface is clean and dry, apply one coat of SportMaster Acrylic Adhesion Promoter. This product acts as a concrete primer and helps the SportMaster color coating system adhere to the concrete. It also helps to lock down potential concrete powder, or efflorescence, that may migrate into the color coating “paint” layers and leave a hazy color hue.

After the Acrylic Adhesion Promoter dries, Acrylic Resurfacer and the colored surface coatings can be applied. There is no special timing required with Acrylic Adhesion Promoter. The successive coatings can be applied as soon as it is dry to the touch, or on another day thereafter.

One or two coats of Acrylic Resurfacer is usually sufficient to fill broom patterns and concrete surface texture on a new concrete court surface. Follow that with SportMaster color coatings, 2 coats minimum, and striping to complete the new concrete recreational court surfacing.