Power troweling is a vital step in preparing post-tension & reinforced concrete tennis courts for a medium broom finish and the application of 100% acrylic coating systems. This process significantly influences the long-term performance, durability, and appearance of the finished court. It also plays a critical role in minimizing issues such as water intrusion, blistering, and peeling of coatings. Here’s why power troweling is essential:

- Creates a Dense, Uniform Surface

- Power troweling compacts and smooths the fresh concrete surface, resulting in a dense and consistent slab.

- This uniformity is especially important for post-tension concrete, which is subject to internal stresses and movement. A properly troweled surface helps minimize future irregularities and maintains the structural integrity of the slab.

- It also ensures the surface is level and free of significant high or low spots, which helps support proper water drainage and uniform coating coverage.

- Minimizes Surface Capillaries

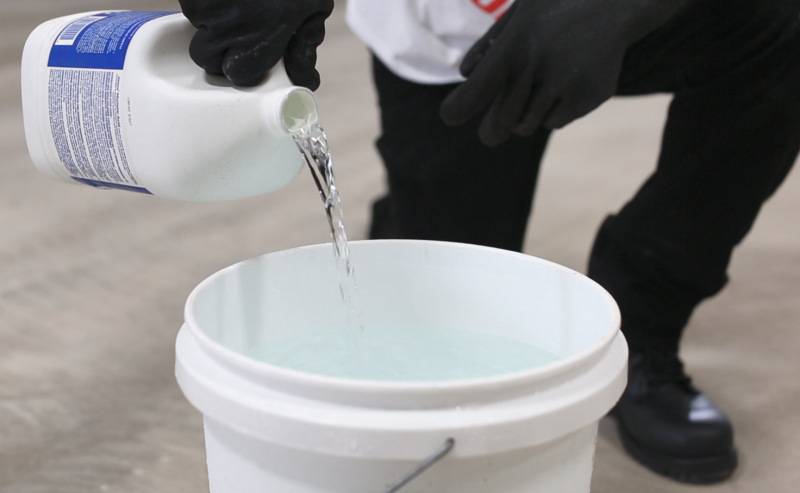

- One of the key benefits of power troweling is the reduction of surface capillaries—the tiny channels within uncured concrete that can absorb and transport moisture.

- By densifying the surface and closing these capillaries, power troweling significantly reduces the potential for moisture intrusion from below or within the slab.

- This is crucial for preventing issues like blistering, bubbling, or peeling of acrylic coatings, which are often caused by trapped moisture vapor escaping through the coating system after application.

- Establishes a Stable Base for Broom Finish

- Once the concrete is troweled, a medium broom finish can be applied to create a uniform surface texture that is ideal for coating.

- Troweling ensures the broom finish is laid over a stable, well-consolidated substrate, which enhances its uniformity and reduces surface variability.

- This consistency supports an even coating application and contributes to the overall aesthetic and performance quality of the court.

- Improves Coating Adhesion and Performance

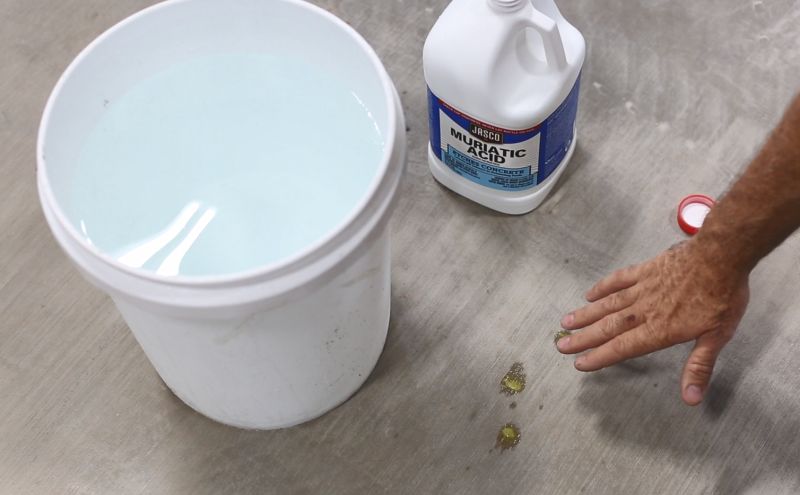

- 100% acrylic coatings require a clean, sound, and stable surface to bond effectively.

- A troweled surface provides fewer voids and eliminates surface laitance or dusting that could otherwise interfere with coating adhesion.

- This enhances the mechanical bond between the concrete and the coating system, reducing the likelihood of premature failure and helping the surface withstand environmental stressors over time.

- Increases Resistance to Surface Defects

- Power troweling helps prevent common surface issues such as:

- Dusting

- Micro-cracking

- Surface flaking or scaling

- These defects, if left untreated, can compromise the performance and appearance of both the concrete and the coating system.

- By producing a smooth, consolidated surface, troweling extends the functional life of the court.

- Aligns with Industry Standards

- The use of power troweling followed by a broom finish is consistent with the American Sports Builders Association (ASBA) guidelines and coating manufacturers’ recommendations.

- Following these best practices helps ensure the finished court meets performance, durability, and warranty standards.

Conclusion

Power troweling is not simply a finishing step—it’s a crucial part of preparing post-tension concrete tennis courts for a high-performance acrylic coating system. It enhances surface uniformity, minimizes capillary pores to reduce water intrusion, and ensures a stable base for both the broom finish and coatings. These benefits collectively prevent coating failure and extend the life and quality of the court. Proper troweling sets the foundation for a durable, professional-grade playing surface.