With the high volume of concrete pickleball courts being built, the common question “Do concrete pickleball courts need saw cuts or expansion joints” comes up frequently.

The short answer is “maybe”.

Saw Cuts & Expansion Joints | Pickleball Courts

The American Sports Builders Association provides up-to-date construction guidelines for sport surfaces in the US and abroad. In conjunction with USA Pickleball, the governing body of pickleball, ASBA created a book with pickleball court standards. This book is utilized by architects, engineers and other pickleball courts specification writers.

Currently, the recommended substrates for pickleball courts are asphalt & post-tensioned concrete. Post-tensioned concrete slabs are supported by a grid of steel tendons in a protective sheath that are tensioned after the concrete is placed. These slabs are considered crack-resistant due to the support of the tensioned cables and do not need saw cuts or expansion joints.

Why are saw cuts & expansion joints placed in concrete?

Concrete is a very hard substrate, and it’s very important that the sub-base is properly laid, sloped for drainage & compacted. Another popular concrete construction method is reinforced concrete. Reinforced concrete slabs contain rebar, or steel reinforced bars that lend extra strength within the concrete slab. For most applications, like driveways, saw cuts are placed after the concrete is formed to control cracking. However, once the saw cuts are placed, you always have a cut through the slab that will open and close during expansion and contraction from temperature swings. The saw cuts are straight and consistent, to minimize random cracking in varying directions.

Pickleball & Athletic Courts on Reinforced Concrete

Previous specifications through the ASBA mentioned use of reinforced concrete for tennis courts. Tennis Courts are 60′ x 120′ and the recommendations were to place saw cuts under the net line and between adjacent courts. This prevented cuts in the playing areas and potential vertical displacement, or trip hazards, for the players. Based on the tennis court saw cut recommendations, you basically had two 60′ x 60′ slabs with no saw cuts on each side of the net. Pickleball courts are usually 30′ x 60′, so many people choose to only put a saw cut under the net line to avoid visible cracks and potential heaving of the slabs between joints.

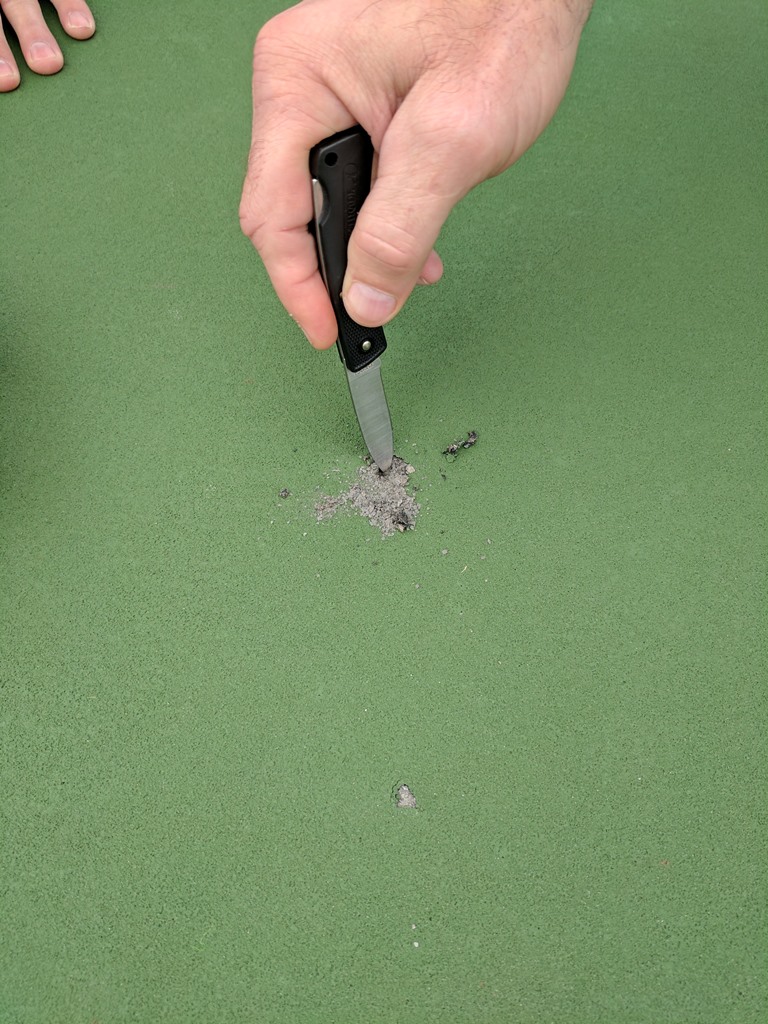

Acrylic Crack Filler | Uses and Longevity

Acrylic crack fillers are usually applied before application of court coatings to fill the saw cuts. This helps to keep the coatings from puddling in the joints and maintain a cleaner look. However, movement in the joints will cause a hairline crack to appear, which will gradually widen. Some joints will reopen quickly and others may take longer to appear, depending on the amount of movement and moisture under the court. Crack fillers can be reapplied as needed, to minimize moisture intrusion, but this is a continuing maintenance cycle. The saw cuts/expansion joints are doing their intended job by allowing movement to minimize stress on the rest of the slab.

Flexible and Elastomeric crack fillers

There are also flexible elastomeric fillers that can be used in saw cuts and expansion joints. These products have better elongation in the cracks, but they can also lead to other issues. In some cases, the flexible fillers can be pushed upwards when the slabs come back together, leaving a small hump that sticks up above the joints. This is not ideal for safe footing and consistent ball bounce. They can also slump when the slabs move apart, leaving a small valley in the saw cuts. For these reasons, many opt for the harder sand and cement filled acrylic crack sealants. These situations are solely dependent on the construction of the court and weather variables. Indoor courts are usually more consistent due to indoor temperature control and the saw cuts usually exhibit less movement than outdoor slabs.

Can I Avoid Seeing Saw Cuts on my Pickleball Court?

Here are some of the best ways to avoid seeing saw cuts on your pickleball court:

- Management by construction methods

- Post-tensioned concrete or asphalt construction

- Minimizing saw cuts by strategic placement (under the net line and out of playing area)

- Crack fillers (temporary methods and reapplication)

- Note* reapplying crack fillers will likely leave unsightly shade differences over the cracks.

Remember, saw cuts are uniform and are designed to prevent breakage and cracking throughout the slab. If the cracks open, they are preventing additional damage to the slab and other random cracks. Asphalt courts are a bit more flexible, but the asphalt binders will also become brittle with age and will become more susceptible to cracking and settling. Compaction, drainage and overall construction is also important to longevity of asphalt courts.