Tennis court surfaces can be customized to achieve very specific speed of play. The ITF (International Tennis Federation) has a technical testing program to classify all kinds of tennis court surfaces into court pace ratings (CPR). Here is the current chart of CPR and pace category:

- Category: Slow | CPR less than or equal to 29

- Category: Medium-slow | CPR 30-34

- Category: Medium | 35-39

- Category: Medium-fast | 40-44

- Category: Fast | greater than or equal to 45

Customizing Acrylic Court Surfaces

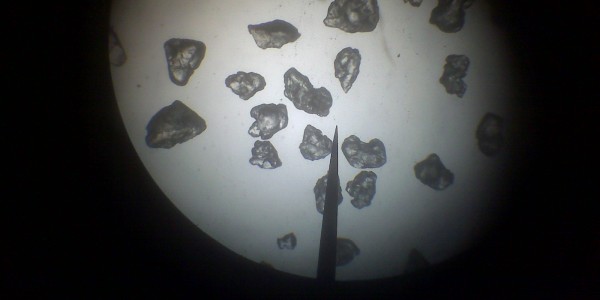

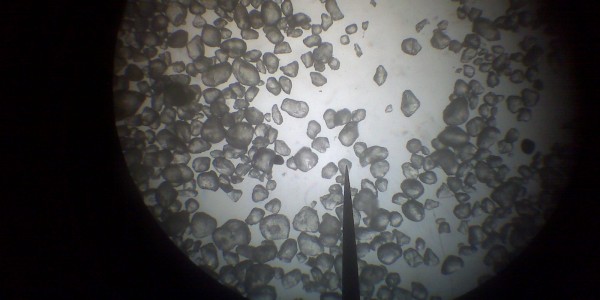

Most tennis court surfaces can be customized to some extent. However, acrylic court surfaces have the widest flexibility of options. Due to the ability of acrylic coatings to suspend different blends of silica sand and specialty aggregates, they can generally achieve all ITF paces with the correct combination of texture.

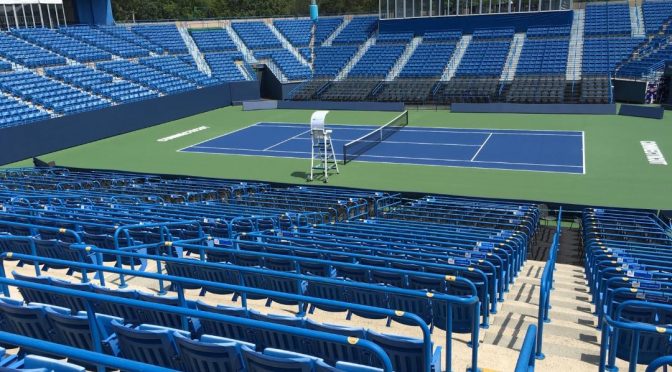

Professional Tennis Tournament Surfaces

When it comes to professional tennis tournament surfaces, the speed of play is very important. The court surfaces are usually kept consistent to the other tournaments in the same series. This enables the players to hone their game on courts that perform similarly, prior to the most prestigious event at the end of the swing.

College & University Tennis Court Surfaces

College & university tennis court surfaces are also commonly resurfaced to meet specific court speeds, depending on the current strengths and weaknesses of the players. Many times, the tennis coach will prefer a slower court to help the home team if they lack power serves and pride themselves on volley or returning the serve. On the other hand, fast court surfaces favor the player with a fast serve.

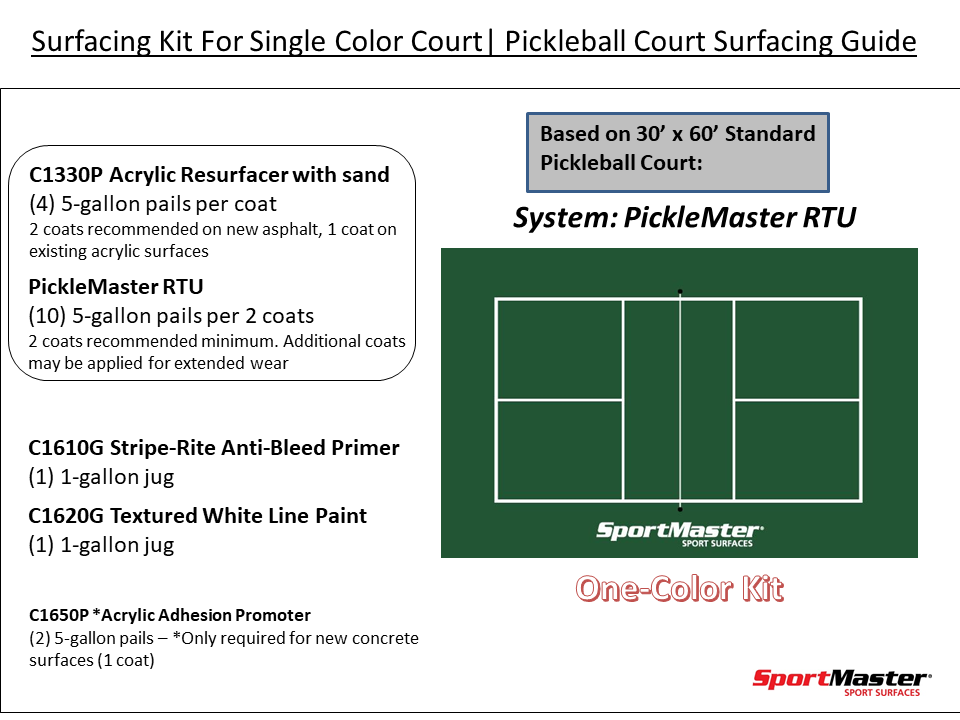

Recreational Court Surfaces | Safe Texture

Recreational court surfaces normally require a safe texture, and are usually installed at a medium speed of play. This ensures that the court surfaces have enough grip for common dry or wet conditions. If players happen to play on the courts during or after rain, or when dew is still present, there will be minimal chances for slipping and falling from slick surfaces. This surface pace is well suited for all sports from tennis, basketball, and pickleball to recreational play.

Sport Surfacing Systems | Installers

To learn more about speed of play and creating the ideal surface conditions for your sport surfacing systems, contact a SportMaster representative. They can assist with apples to apples specifications and put you in touch with an experienced contractor to install the coating system to the manufacturer specified pace.