Sport and game courts are as popular as ever, especially with the extreme growth of sports like pickleball and continued popularity of basketball, tennis and multi-sport games and courts.

SportMaster has a multitude of durable and vibrant acrylic surfacing systems that are designed for asphalt or concrete courts. Each substrate has a somewhat different approach to preparation, prior to application of the sport surfaces. We are going to discuss a common step that is required when coating concrete courts for the first time. This process is called acid etching or acid washing.

What Is Acid Etching? | Concrete Court Surfacing

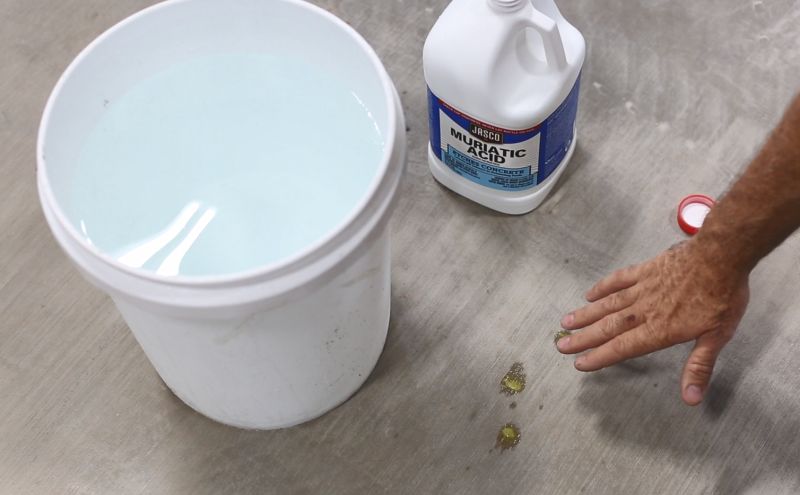

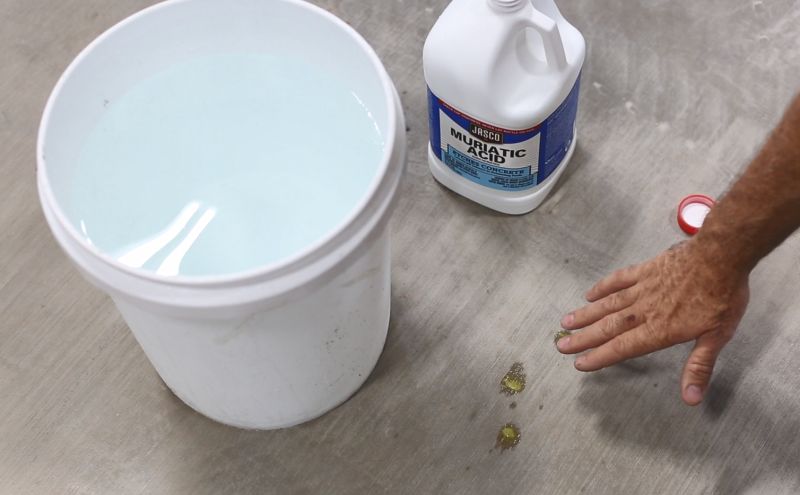

Acid etching is the process of pouring a mixture of water and acid on a fully cured concrete slab. Generally, either muriatic or phosphoric acid is used, but muriatic is a bit easier to find. In a nutshell, acid etching promotes an ideal environment for chemical bond of coatings to concrete. If done properly, acid etching only has to be performed once. If a concrete slab has not been acid etched or coated, even years after it was built, it’s always a good idea to do it.

Why do I Need To Acid Etch My Concrete Court Surface?

Concrete goes through a chemical curing process after it is poured. It takes 28 days for a concrete slab to completely cure. There is a good bit of water in the concrete mix and as the concrete is curing, water is continuously wicking and evaporating upward and out of the slab. As the water is migrating upward, it brings efflorescence, or salts, that reside in the concrete. After the initial curing phase is complete, there is a crust of efflorescence on the surface of the concrete.

Lesson In PH & Surface Chemistry

PH, or “potential of hydrogen” is the scale of acid vs base. The PH scale goes from 0 to 14, whereas 0 is very acidic and 14 is very basic (alkaline). For ideal chemical adhesion, coatings prefer a neutral environment. This would be 7 on the PH scale. When concrete cures, the surface crust or salt deposits, are very high in alkaline (a PH around 13.5). The process of acid etching neutralizes the high alkaline crust and brings the surface PH back to neutral. The acid washing process also helps to break down and rinse away the powdery efflorescence. This also prevents flaking or peeling of coatings & migration of powder into the color coatings resulting in a cloudy appearance.

How To Acid Etch A Court | Pickleball – Basketball – Tennis

In this section, we will outline how to acid etch a concrete court surface. But first, here are a few pointers:

- Make sure to acquire and wear adequate safety gear, when working with acid. Thick rubber gloves, safety glasses, and relevant clothing and boots. Avoid breathing in the direct fumes of concentrated acid and ensure that you have plenty of air flow when inside.

- As a general guideline, it should take around 2 to 3 gallons of acid to etch a smaller court, like a 30′ x 60′ pickleball court & around 8 to 9 gallons for a full tennis court (60′ x 120′).

- Protect any sensitive plants or surrounding materials around the border of the court. Even though you will be rinsing off acid that is very diluted and has already reacted with the surface, it’s a good idea to minimize contact as much as possible.

Step 1: Spray water on the court to dampen the surface. This helps the mixed acid and water to flow and better penetrate the surface.

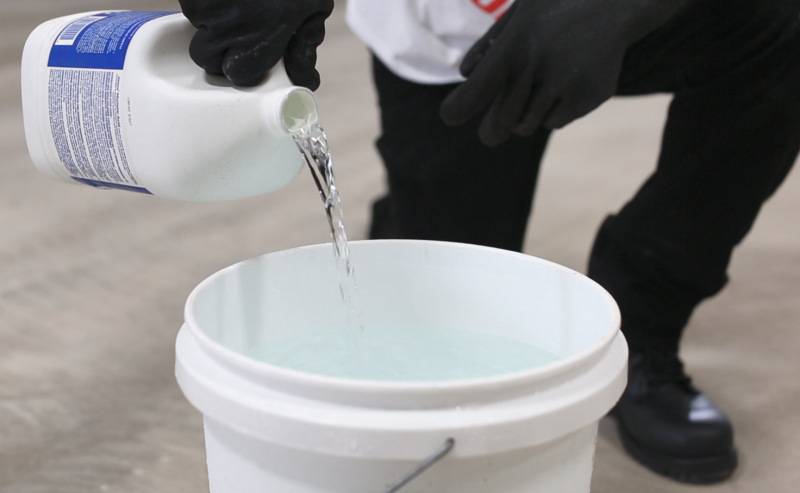

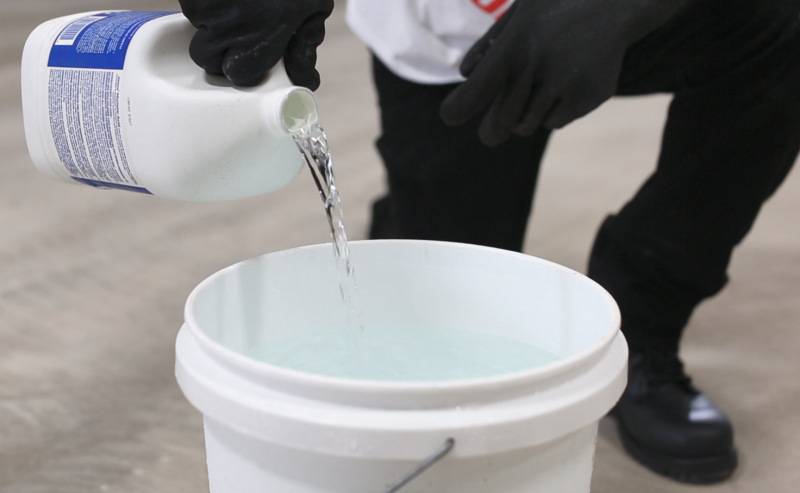

Step 2: Properly mix the acid and water, following the dilution measurements on the acid bottle. There should be directions for “masonry etching” on the bottle instructions. Remember to fill the empty bucket with water first and then pour the correct amount of acid into the water. This helps to prevent splashing of acid.

Step 3: Pour the acid & water mixture onto the concrete, working in small areas or sections at a time. If you’re able to have a helper, have the 2nd person immediately broom the solution around with a push broom to make sure the acid comes into contact with every square foot of concrete. Make sure that you don’t pour the acid mixture and expect it to span a long distance. Instead, pour around a small zone in a tight “s” pattern to ensure direct contact with the surface. Since the acid mixture reacts instantly with concrete, the potency diminishes as it spreads.

You will notice a cloudy appearance in the liquid and minor bubbling reaction, which means the acid is working to neutralize the surface salts.

Step 4: As you move on from section to section, you will notice the reaction dissipates in the previously treated area. At that point, you can rinse those areas off to flush surface contaminants and move the neutralized acid solution off the court surface. If possible, it’s best to start on the high end of the court and slowly move all of the water toward the low end of drainage. If possible, try to keep the entire court damp throughout the process, which keeps the sediment from sticking to the surface.

Step 5: After you have etched the entire court surface, and rinsed away most of the remaining acid mixture and sediment, it’s always good to do a final rinse of the entire surface. This ensures a completely clean surface, free to any potential acid or other contaminants. If you’re indoor and don’t have available drains, a floor cleaner machine can be used for a good final cleaning.

*Remember to protect and avoid adjacent concrete areas that are not receiving the sport coatings, as the acid can create a different color or appearance to exposed concrete. This is hidden when coatings are applied over the acid etched play areas.

Common Misconception About Acid Etching

Many people think that acid etching creates a physically textured surface for the coating to adhere. This is not the case, as the actual purpose was established earlier in this bulletin. It is still very important for the concrete surface to have a medium-broom finish or similar. That is very important for physical adhesion of coating systems. Remember, the two most importance factors for good adhesion of sport coatings is:

- A good surface texture/profile for physical adhesion

- Neutral surface PH for excellent chemical adhesion