Question: Why do tennis courts crack under the tennis net?

Answer: Tennis courts often develop cracks under the tennis net for a few related reasons:

- Tension on the cable that supports the tennis net

- Concrete footers that hold the tennis net posts in place

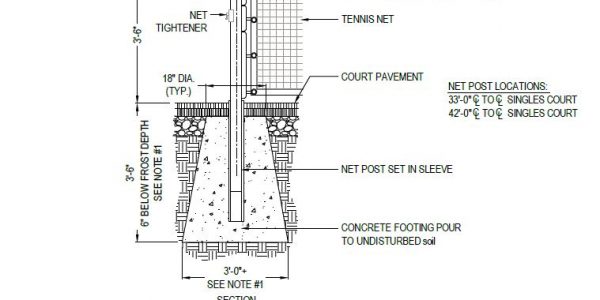

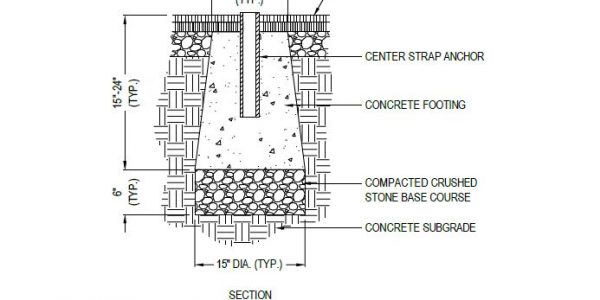

Tennis court net posts are secured by a concrete footer, when installing an asphalt tennis court. The footer can be in place prior to the asphalt paving process or it can be installed after the tennis court has been paved. There is a plastic or galvanized sleeve set within the net post footer, which makes the net post removable and easily replaceable.

Tennis nets are suspended by a cable, which is secured to the dead-end post, and wound or tightened with a wind assembly from the other post. The average recommended tension on the net cable is 400 to 450 lbs. The sustained tension from the cable tends to pull the post footers in and can often create cracks into the surrounding asphalt. Square or rectangular footers will often send cracks from the corners into the surrounding asphalt. Round footers can also create cracks under the net, so it’s best to consult with an experienced court builder or resurfacing company to discuss the proper way of installing net post footers.

Here are some diagrams that show the right way to shape and install the court footers, to minimize inward shifting:

Concrete & Asphalt Surfaces

Concrete and asphalt expand and contract at a different rate. When concrete is place next to asphalt, the gap between them will likely exhibit movement. This can also happen with light posts, fence posts, shade structures, and other amenities.

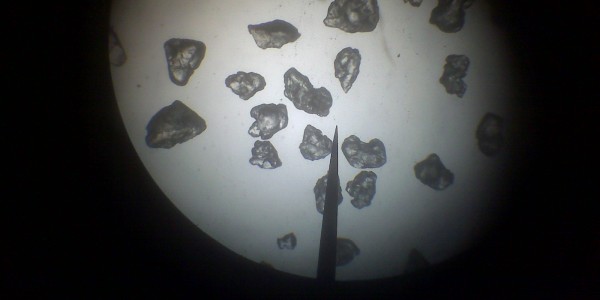

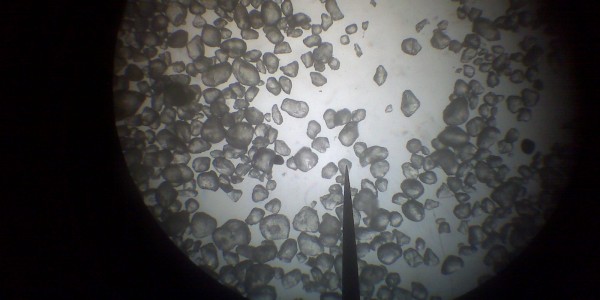

Here are a few more pictures showing cracks under and around the tennis court net line:

Filling Cracks On Tennis Courts

Once the cracks have started, it’s all about maintenance. SportMaster produces easy-to-apply crack fillers and sealants. These products are not a structural fix, but more of a “band-aid” for cracks. They will minimize the amount of water that flows through the cracks and into the base of the court. Water can loosen the compacted base, and expand to create more damage during freeze-thaw periods.

If the cracks are larger than an inch wide, and very deep, we recommend having a professional tennis court contractor take and look and provide recommendations. Many times they will need to fill the large cracks with concrete, asphalt, or other specialized means. At some point, reconstruction or an overlay is the best long-term solution.